Branded Interiors

Branded Interiors

A key component of place making is our twenty-five plus years of branded interiors for retail and hospitality focused projects. We are accustomed to the fast pace of design, engineering, production and installation to open high quality environments that support brands on time and within budget. We support architects and brands from early concept to completion including the development of materials, mockups and final production of materials and systems for interiors. We are proactive from day one to support both the aesthetic and performance aspirations of each branded interior from concept through commissioning.

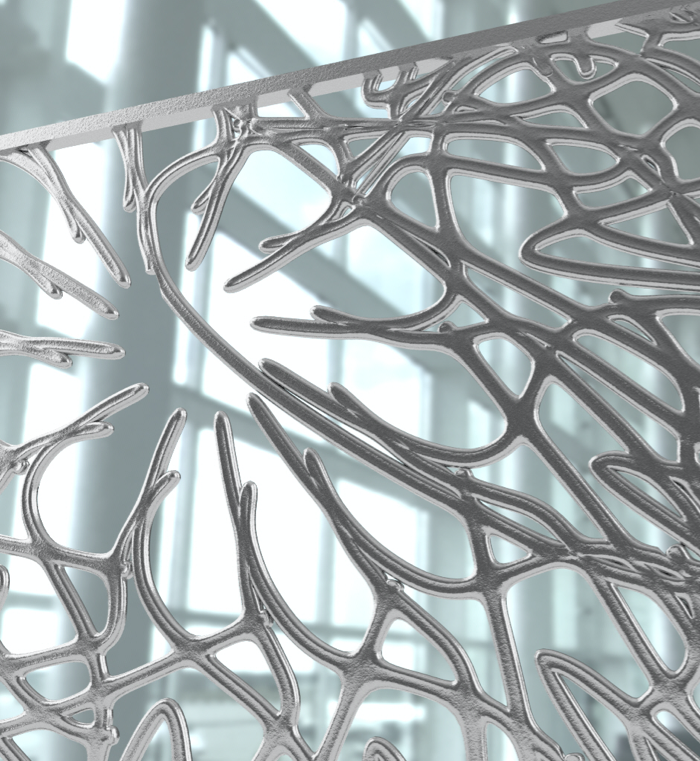

Material Applications

We are a material specialist with a vast portfolio of inventive materials that cross the full spectrum of unique elements for branded interior applications. Our team of engineers, architects, industrial designers and researchers draw from both traditional interior material technologies and adaptive technologies from aerospace, automotive and composite industries. This broader range of materials gives architects and brand clients distinctive aesthetic and high-performance options that will differentiate their branded interiors from other brands.

Concept Design/Charrettes

Design concepts often coalesce quickly and if the branded interior elements are not considered from the beginning the integration can become complicated. By engaging at the beginning of the project at approximately the same time as the conceptual design we can support a collaborative dialog about how materials can integrate with the structure and other important design elements. We are well known for facilitating material design charrettes with design architects, brand clients, engineers and construction teams.

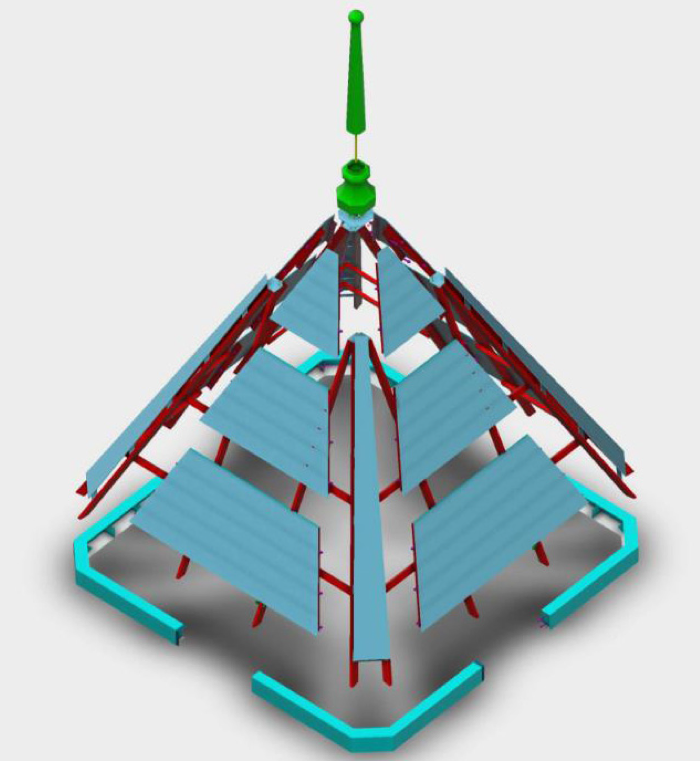

3D Modeling

Nothing brings clarity to complex façade surface planes like 3D modeling. We utilize a range of specialized software to capture façade structure, parametric and curvilinear surfaces. In addition to utilizing static 3D imagery, we can animate complex elements to determine the movement of operable elements including large doors, access panels and other interior architectural features.

Photo Realistic Rendering

Our skilled drafting teams create 3D models during the concept and charrettes to assist stakeholders understand the spatial, massing and materiality of interior branded elements. Beyond the illustrative benefits the larger overall renderings can support regulatory approvals, material selections and budget decisions. We often deploy our photo realistic rendering for projects by offering imagery with a myriad of options.

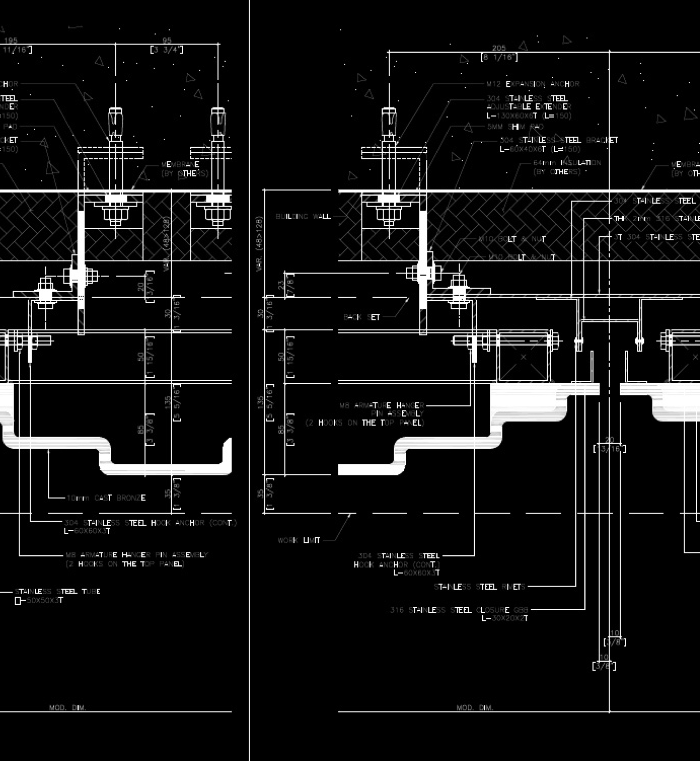

Construction Documents

The genesis of our construction documents begins early on during concept or schematic design. As the architect’s design evolves our façade details, materiality and integration with other aspects of the building take form. The building retail façade construction documents are all encompassing detailed specifications outlining related building elements, performance criteria, materials, installation, operations, maintenance and warranties.

Visual Mockups

A key part of the retail façade aesthetic design is the creation of visual mockups that capture the architect’s visual concept. It is especially helpful to understand the massing, sightlines, shadows, reflections and opposing material finishes. We often recommend that the visual mockups have interchangeable materials so the architects can experiment with varying combinations of glass, metal, earthen and composites.

Quantity Surveys | Unit Cost Estimates

Quantity and cost guidance from concept through construction documents supports the value-based design and performance aspects of the branded interiors. Without properly executed quantity surveys and unit cost estimates the project may be run through the value engineering gauntlet which typically requires comprises that are less than desirable. Our vast experience in the development of pictorial takeoffs and knowledge of materials and system cost in each local market we serve mitigates underestimating quantities and cost overruns.

Fabrication/Assembly

Once submittal drawings have been approved our seasoned team of production management implements the production methods to ensure that the design intent is carried throughout the production and assembly process. The façade elements are factory finished and assembled to the greatest extent possible to minimize field fit and finish. Our stringent quality control standards ensure that the retail façade comes together within tolerances to meet or exceed the branding expectations.

Install-Assist

Our Project Managers are well trained in rigging and installation of branded interiors worldwide. During construction planning and during the kickoff of construction we mobilize a Project Manager to work with the client’s designated installer to address equipment requirements, sequence of construction, tolerances, integration with other trades and protection of installed material during construction.